What are Smart Surfaces with Antiviral Coatings?

Smart Surfaces with Antiviral Coatings are engineered materials designed to deactivate viruses and bacteria on contact. These surfaces often use metal ions (like copper or silver), photocatalytic coatings (like titanium dioxide), polymeric agents, or nanotechnology-based particles.

They are becoming essential in:

- Healthcare facilities (hospitals, medical devices, PPE)

- Public spaces (transportation, schools, offices, hotels)

- Consumer goods (electronics, wearables, appliances)

- Automotive and aerospace interiors

- Food safety and packaging

These coatings reduce infection risks, cut cleaning costs, and improve overall safety.

How do Smart Surfaces with Antiviral Coatings work?

The functionality depends on the type of coating:

- Metal-based coatings: Release ions (silver, copper, zinc) that disrupt virus membranes.

- Photocatalytic coatings: Use light to activate titanium dioxide, producing reactive oxygen species that kill viruses.

- Polymeric coatings: Embed antiviral agents that are gradually released over time.

- Nanotechnology-based coatings: Leverage nanoparticles that mechanically or chemically damage pathogens.

This multi-technology approach ensures broad protection against viruses, bacteria, and fungi.

Why are Smart Surfaces with Antiviral Coatings important for healthcare?

Healthcare settings are high-risk environments where hospital-acquired infections (HAIs) cost billions annually.

Key healthcare benefits:

- Infection control: Reduced HAIs and surgical infections.

- Improved patient safety: Protection for immunocompromised individuals.

- Operational efficiency: Lower cleaning and maintenance costs.

- Compliance: Aligns with global safety and hygiene standards.

For hospitals, these coatings can mean fewer outbreaks, lower costs, and safer environments.

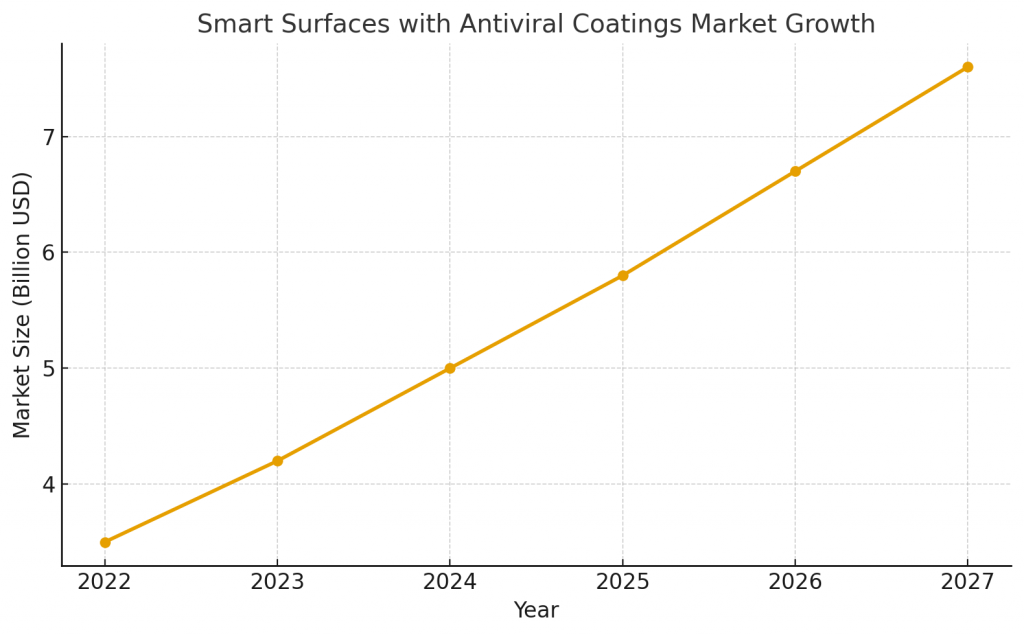

What is the current market size of Smart Surfaces with Antiviral Coatings?

The global market for Smart Surfaces with Antiviral Coatings is growing rapidly.

- Market size: Expected to reach $7.6 billion by 2027, growing at 12.1% CAGR.

- Key sectors driving growth: Healthcare, public infrastructure, consumer electronics, and packaging.

- Geographic hotspots: China, Europe, and Korea lead in patent filings and commercialization.

This growth is driven by post-pandemic awareness, regulatory pushes, and technological innovations.

Which companies are leading Smart Surfaces with Antiviral Coatings?

Established companies include:

- PPG Paints – Copper Armor™ antimicrobial paint.

- Sherwin-Williams – Large investments in antimicrobial R&D.

- AkzoNobel – Expanding antiviral coatings in Asia.

- Nippon Paint – Photocatalytic antiviral coatings.

- Corning – Guardiant® antimicrobial particles.

- Albini Group – Antiviral fabrics with HeiQ collaboration.

Startups and innovators include:

- HeiQ Materials – Silver and plant-based antimicrobial additives.

- GrapheneCA – Graphene-based antiviral coatings.

- NanoSeptic – Self-cleaning antimicrobial surfaces.

- EnvisionSQ – NanoCleanSQ disinfectant applications.

- NanoShield – Copper nanoparticle spray coatings.

Together, these players are building a strong innovation pipeline.

What is the TRL (Technology Readiness Level) of Smart Surfaces with Antiviral Coatings?

TRL indicates how close a technology is to commercialization.

- Metal-based coatings: TRL 9 (fully commercial, global adoption).

- Polymeric coatings: TRL 9 (widely adopted in textiles and healthcare).

- Photocatalytic coatings: TRL 8 (emerging, strong research activity).

- Nanotechnology-based coatings: TRL 8 (promising, still maturing).

Takeaway: Metal and polymeric coatings are market-ready today, while nanotech and photocatalytic coatings will dominate the next wave.

Which universities are researching Smart Surfaces with Antiviral Coatings?

Top global research hubs include:

- Northumbria University (UK): Antiviral coatings for everyday surfaces.

- University of Birmingham (UK): Nanocoatings for infection prevention.

- HKUST (Hong Kong): MAP-1 polymer coating.

- Princeton University (USA): Zinc-embedded fabrics for masks.

- Cambridge University (UK): Antiviral mask coatings.

- ETH Zurich (Switzerland): Nanoparticles to kill resistant bacteria.

- University of Liverpool: Antimicrobial surfaces innovation hub.

These universities are driving the next wave of antiviral surface innovation.

What standards apply to Smart Surfaces with Antiviral Coatings?

For market approval, compliance with ISO, ASTM, and JIS standards is essential.

- ISO 21702:2019 – Antiviral activity on plastics.

- ISO 18184:2025 – Antiviral textiles testing.

- JIS Z 2801 – Antibacterial testing on plastics.

- ISO 27447:2019 – Photocatalytic antibacterial testing.

- ASTM E1053-20 – Virucidal testing on surfaces.

- ISO/TS 23650:2021 – Nanotechnology textiles antimicrobial testing.

Following these standards boosts credibility and speeds up commercialization.

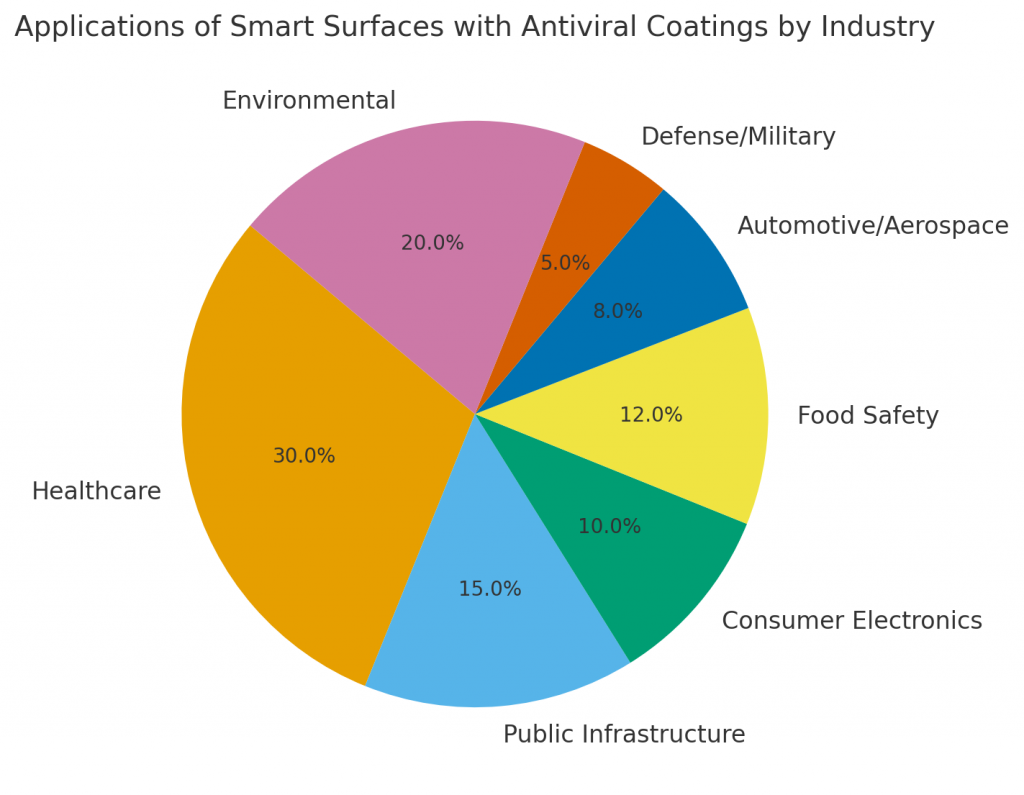

What are the main applications of Smart Surfaces with Antiviral Coatings?

High-value applications include:

- Healthcare: Hospital surfaces, PPE, surgical tools.

- Public infrastructure: High-touch transit areas, schools, offices.

- Consumer electronics: Smartphones, laptops, wearables.

- Food safety: Active packaging to reduce contamination.

- Automotive & aerospace: Self-disinfecting interiors.

- Defense: Antiviral uniforms, field hospitals.

The impact is multi-industry, creating opportunities across B2B and B2C markets.

What is the future outlook for Smart Surfaces with Antiviral Coatings?

The future is promising, with short, medium, and long-term milestones:

- Short-term (1–3 years): Copper/silver coatings in hospitals and transit systems.

- Medium-term (3–5 years): Graphene-based coatings and antiviral electronics.

- Long-term (5–10 years): IoT-enabled antiviral surfaces, self-healing films.

- Very long-term (10+ years): AI-designed coatings, space-grade antiviral materials.

These innovations will reshape healthcare, electronics, and public safety.

How can PatentsKart help with Smart Surfaces with Antiviral Coatings?

PatentsKart can be your strategic IP partner in this growing field.

We help innovators, startups, universities, and enterprises by:

- Patent Landscape Analysis: Understanding competitors’ filings.

- Freedom-to-Operate (FTO) Searches: Ensuring you avoid infringement.

- Patent Drafting & Filing: Securing strong IP protection.

- Licensing Support: Identifying monetization opportunities.

- R&D Collaboration: Connecting with universities and consortia.

Our expertise ensures you can innovate confidently while staying legally protected and market-ready.

Conclusion

Smart Surfaces with Antiviral Coatings represent a transformative technology for healthcare, electronics, infrastructure, and beyond. With mature TRL levels, strong patent activity, clear standards, and high market growth, this sector offers both commercial opportunities and societal benefits.

Whether you are a researcher, a startup, or a large enterprise, this is the right time to secure IP, build partnerships, and scale innovations. With PatentsKart by your side, you can confidently lead in the antiviral coatings revolution.

FAQs

1. What industries benefit most from Smart Surfaces with Antiviral Coatings?

Healthcare, consumer electronics, automotive, aerospace, food packaging, and public infrastructure benefit most due to high-touch use cases.

2. Are Smart Surfaces with Antiviral Coatings safe for humans?

Yes, when tested under ISO and ASTM standards. Regulatory approvals ensure coatings are non-toxic and safe for everyday contact.

3. How long do Smart Surfaces with Antiviral Coatings remain effective?

Many coatings remain effective for months to years, depending on material type (e.g., copper coatings can last up to 5 years on surfaces).

4. What is the biggest challenge in adopting Smart Surfaces with Antiviral Coatings?

Scalability, durability testing, and regulatory approvals are the main hurdles before mass-market adoption.

5. How can companies protect their innovations in Smart Surfaces with Antiviral Coatings?

By filing patents, conducting FTO searches, and working with IP experts like PatentsKart to secure strong intellectual property strategies.