What Are Direct Air Capture Modular Units and Why Do They Matter?

Global efforts to address climate change depend on two strategies: reducing emissions and actively removing carbon dioxide already in the atmosphere. While renewable energy and efficiency address the first, direct air capture modular units (DAC) focus on the second. These systems offer a scalable pathway to remove CO₂ directly from ambient air and lock it away for centuries.

Unlike traditional carbon capture systems tied to smokestacks, direct air capture modular units can operate anywhere, making them flexible, location-agnostic tools in the climate tech toolbox. By leveraging modularity, they enable replication at scale, bringing down costs and accelerating deployment in line with global carbon removal targets.

How Do Direct Air Capture Modular Units Work in Practice?

The principle of DAC is simple: pass ambient air over chemical sorbents that selectively capture CO₂, then release it in a pure stream for storage or reuse. In practice, the challenge lies in energy efficiency, material durability, and scalability.

Key steps in DAC operation:

- Air contact: Fans move large volumes of air through absorbers.

- CO₂ binding: Chemicals capture CO₂ molecules while allowing other gases to pass.

- Regeneration: Heat or pressure releases concentrated CO₂ from the sorbent.

- Compression: CO₂ is compressed for transport or injection.

- Storage or use: The captured gas is sequestered underground or used in industrial processes.

When combined with modular architecture, these systems become modular DAC systems that can be scaled up like building blocks, dramatically improving deployment speed.

Why Does Modularity Matter for Scaling Carbon Removal?

Large, centralized DAC plants are capital-intensive and slow to build. By contrast, direct air capture modular units offer several advantages:

- Scalability: Units can be added incrementally to match demand.

- Flexibility: They can be deployed in diverse geographies, including renewable-rich regions.

- Risk management: Smaller modules reduce upfront capital exposure.

- Standardization: Replicable units lower engineering and permitting costs.

- Speed: Prefabricated designs accelerate construction timelines.

In this way, modularity transforms DAC into a viable, distributed solution for global carbon removal.

What Are the Key Benefits of Direct Air Capture Modular Units?

The benefits extend across environmental, economic, and policy dimensions:

- Climate impact: Permanent carbon sequestration reduces net emissions.

- Energy integration: Units can run on renewable power for net-negative results.

- Economic opportunity: New industries for sorbent production, storage, and CO₂ utilization.

- Policy alignment: Supports national climate targets and corporate net-zero pledges.

- Adaptability: Can be co-located with storage sites or CO₂ reuse facilities.

By combining CO₂ capture technology with modular deployment, these systems offer one of the most promising climate tech pathways.

Which Companies Are Leading in Direct Air Capture Modular Units?

Several corporations and startups are shaping the field:

- Climeworks – Operating commercial modular DAC systems in Iceland for carbon removal and storage.

- Carbon Engineering – Developing large-scale DAC facilities with modular components.

- Global Thermostat – Using amine-based sorbents to scale modular DAC systems.

- Heirloom Carbon – Focusing on mineralization-based DAC integrated into modular units.

- Mission Zero – Pioneering electrochemical DAC with modular scalability.

- AirCapture – Providing modular CO₂ capture technology for industrial clients.

These players highlight the diversity of approaches to direct air capture modular units.

Which Startups Are Driving Disruption?

- Noya – Retrofitting cooling towers into modular DAC systems.

- Carbon Infinity – Building low-cost sorbents for DAC modular deployment.

- Capture6 – Integrating DAC with water treatment facilities.

- Verdox – Developing electro-swing adsorption for energy-efficient DAC.

- Removr – Nordic startup scaling modular DAC units for regional carbon removal projects.

Startups emphasize innovation in sorbents, energy use, and deployment models, complementing large players.

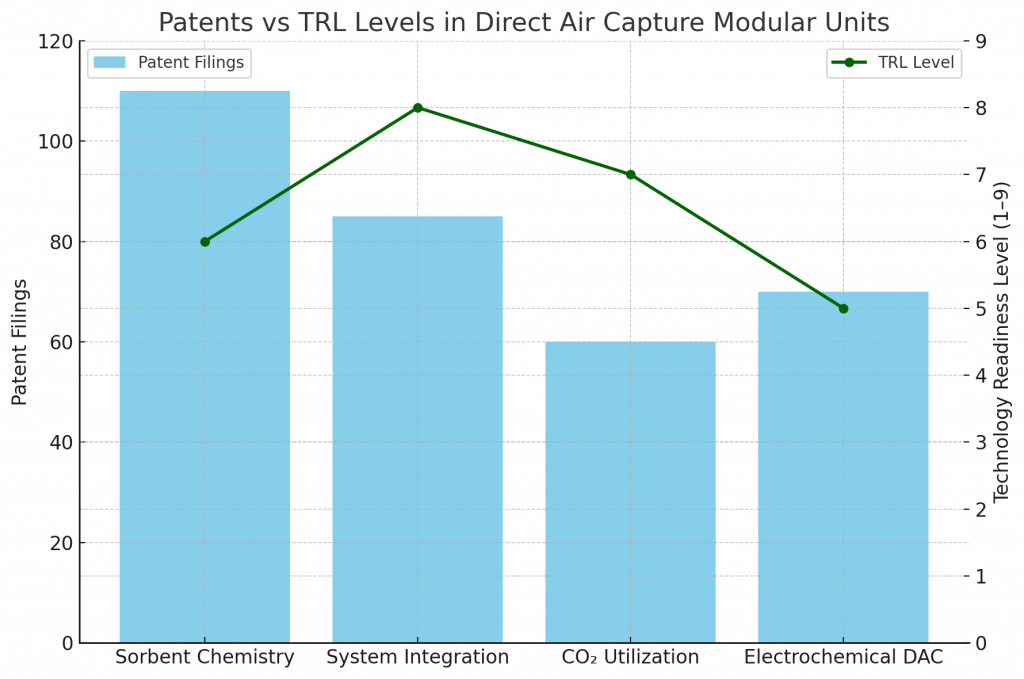

What Do Patents and TRL Levels Reveal About the Field?

Patent activity is strong across several dimensions:

- Sorbent chemistry – Solid amines, hydroxides, and metal-organic frameworks.

- System integration – Patents for modular unit designs and energy recovery systems.

- CO₂ utilization – Conversion into fuels, building materials, or polymers.

Technology readiness levels (TRLs) vary:

- Commercial DAC modules: TRL 7–9, operational in pilot and early plants.

- Novel sorbents: TRL 4–6, promising but still lab-scale.

- Electrochemical DAC: TRL 5–7, moving from lab to pilots.

- Hybrid systems: TRL 6–8, combining capture with direct utilization.

Together, these indicators show a dynamic landscape of climate tech innovation.

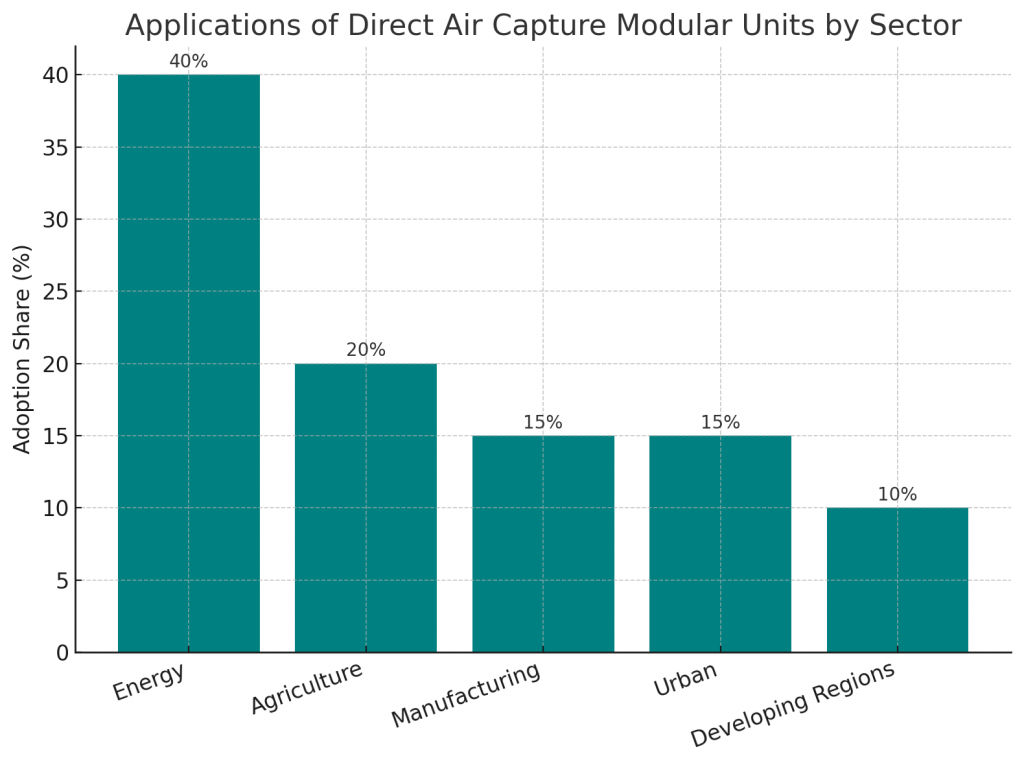

Where Can Direct Air Capture Modular Units Be Deployed?

The modular design allows deployment across industries and regions:

- Energy sector: Offsetting hard-to-abate emissions.

- Agriculture: Coupling DAC with sustainable agriculture carbon markets.

- Manufacturing: Providing CO₂ feedstock for products.

- Urban settings: Pilot projects integrated into buildings.

- Developing countries: Smaller units accessible to emerging economies.

This versatility underlines why direct air capture modular units are central to the global carbon removal strategy.

What Are the Current Challenges?

Despite promise, hurdles remain:

- High costs: Current capture costs range from $400–$600 per ton.

- Energy demand: Requires abundant renewable energy to avoid offsetting gains.

- Infrastructure: CO₂ transport and storage networks need expansion.

- Policy dependence: Incentives and carbon pricing are critical for viability.

- Public perception: Concerns over land use and long-term storage safety.

Addressing these issues will be key to scaling direct air capture modular units.

What Is the Future Outlook for DAC Modular Units?

Looking ahead, three trends stand out:

- Cost reduction: Learning curves and mass production lower costs toward $100/ton.

- Integration: DAC coupled with hydrogen, cement, and aviation sectors.

- Policy support: Expanding tax credits, grants, and international carbon markets.

With these developments, direct air capture modular units could evolve from demonstration projects to mainstream climate solutions.

How Can PatentsKart Help Innovators in DAC?

PatentsKart provides critical IP intelligence for companies advancing direct air capture modular units:

- Patent landscapes to identify innovation gaps.

- Freedom-to-operate reviews to avoid litigation risks.

- Competitor tracking for strategic positioning.

- TRL-aligned roadmaps to guide commercialization.

- Partnership scouting for joint ventures and licensing.

With our expertise, innovators can accelerate deployment while protecting competitive advantage.

Conclusion

As the climate crisis intensifies, scalable carbon removal becomes non-negotiable. Direct air capture modular units provide a viable, flexible, and replicable solution that aligns with global net-zero goals. By combining innovative sorbents, modular designs, and supportive policies, these systems can transform the way we think about atmospheric carbon.

For startups, corporates, and policymakers, the opportunity is clear: invest in direct air capture modular units today to build a sustainable tomorrow.

FAQs

Q1. What are direct air capture modular units in simple terms?

They are systems that pull CO₂ from air using sorbents, packaged in modular blocks that can be scaled easily.

Q2. Why are modular DAC systems better than large plants?

They are faster to deploy, lower risk, and easier to replicate globally.

Q3. Which companies lead in direct air capture modular units?

Climeworks, Carbon Engineering, Global Thermostat, and Heirloom.

Q4. What are the main challenges for DAC modular units?

High costs, energy demand, storage infrastructure, and policy dependence.

Q5. How can PatentsKart help innovators?

By providing IP insights, TRL benchmarking, and partnership support for safe commercialization.