The aviation industry faces immense challenges: safety, efficiency, and sustainability. With increasing global air travel and tighter margins, airlines and aircraft operators must find smarter ways to keep fleets operational. Traditional maintenance approaches—either scheduled or reactive—often result in unnecessary downtime, higher costs, and undetected risks. A revolutionary solution is emerging—predictive maintenance using AI in aircrafts.

This innovation leverages artificial intelligence, machine learning, and sensor data to anticipate equipment failures before they happen. By predicting component wear and optimizing repair schedules, predictive maintenance is transforming aircraft safety, reliability, and operational economics.

What Is Predictive Maintenance Using AI in Aircrafts?

At its core, predictive maintenance using AI in aircrafts is the use of real-time data and AI algorithms to forecast potential failures in critical systems. It replaces outdated calendar-based maintenance schedules with intelligent, condition-based insights.

Key features include:

- AI-driven monitoring: Tracks engine vibration, hydraulic pressure, and avionics performance.

- Machine learning models: Analyze historical and live data to detect anomalies.

- Remaining Useful Life (RUL) estimation: Predicts how long components will last.

- Dynamic alerts: Notifies crews before minor issues escalate.

By combining IoT sensors, AI, and big data, this system ensures safer and more efficient flight operations.

Why Is Predictive Maintenance Using AI in Aircrafts Important?

The importance of predictive maintenance lies in solving aviation’s toughest pain points:

- Safety Enhancement

Human error and unexpected failures are major causes of accidents. AI-based predictive systems mitigate risks by flagging potential malfunctions early. - Operational Efficiency

By preventing unplanned downtime, airlines reduce delays and cancellations, improving customer satisfaction. - Cost Reduction

Avoiding unnecessary part replacements and labor-intensive checks saves millions annually. - Sustainability

Optimized fuel use and reduced spare part waste contribute to greener aviation. - Global Competitiveness

Airlines adopting predictive maintenance gain an edge in operational reliability.

In short, predictive maintenance using AI in aircrafts ensures safety, efficiency, and long-term profitability.

How Does Predictive Maintenance Using AI in Aircrafts Work?

The system combines advanced analytics and smart hardware:

- Data collection: Sensors embedded in engines, landing gear, and avionics continuously record data.

- Cloud platforms: Information is transmitted in real time to predictive maintenance platforms.

- Machine learning models: Algorithms compare live data with historical patterns to detect anomalies.

- Decision support: AI recommends maintenance actions based on confidence levels.

- Execution: Maintenance crews receive alerts, enabling proactive interventions.

By closing the loop from data → AI insights → human action, airlines achieve reliable, cost-effective operations.

What Are the Benefits of Predictive Maintenance Using AI in Aircrafts?

The benefits span across the aviation ecosystem:

- Improved reliability: Aircraft spend more time flying and less time in hangars.

- Reduced costs: Eliminates unnecessary overhauls and parts replacements.

- Passenger safety: Predicts failures before they endanger flights.

- Smarter scheduling: Maintenance aligned with actual component health.

- Sustainability impact: Lower emissions through optimized operations.

Airlines embracing predictive maintenance using AI in aircrafts achieve both economic and environmental gains.

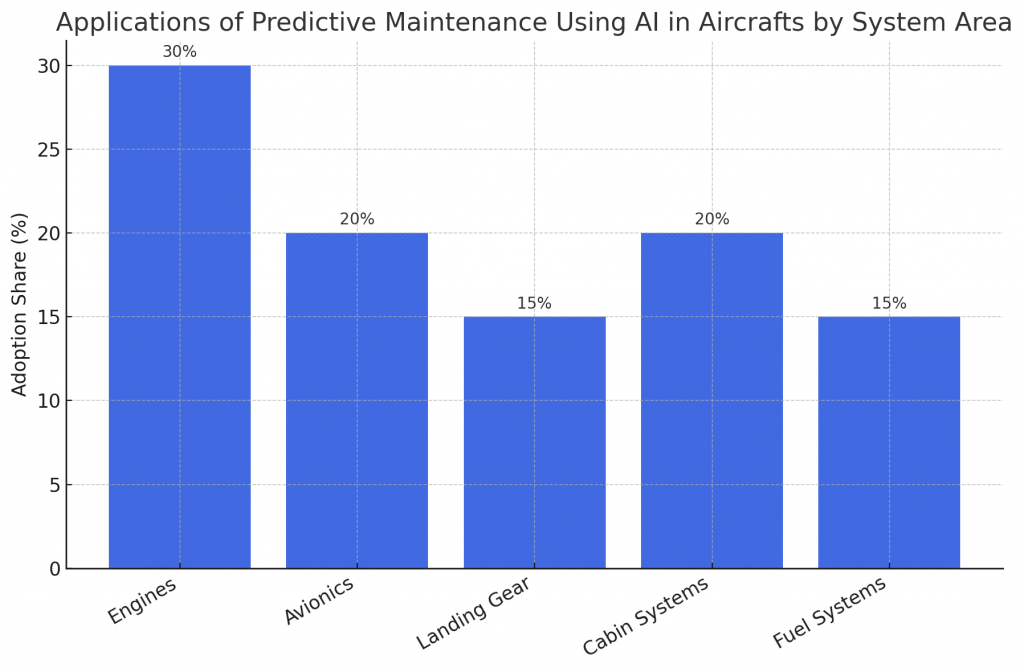

What Are the Applications of Predictive Maintenance in Aviation?

Applications cut across critical systems:

- Engines: Early detection of overheating or vibration anomalies.

- Avionics: Identifying electronic and navigation faults before they escalate.

- Landing gear: Predicting wear and preventing costly failures.

- Cabin systems: Monitoring HVAC, lighting, and in-flight entertainment for reliability.

- Fuel systems: Optimizing consumption and detecting leaks.

Each application ensures improved safety, efficiency, and passenger trust.

Which Companies Are Leading in Predictive Maintenance Using AI in Aircrafts?

Several corporations are already leading adoption:

- Airbus (Skywise platform): Fleet-wide predictive analytics.

- Boeing (AnalytX): Big data-driven maintenance optimization.

- GE Aviation: Digital twins for real-time monitoring.

- Rolls-Royce (TotalCare): AI-powered engine maintenance services.

- Lufthansa Technik (AVIATAR): Advanced predictive maintenance ecosystem.

These leaders showcase how predictive maintenance using AI in aircrafts is moving from pilots to large-scale deployment.

Which Startups Are Innovating Rapidly?

Agile startups are also reshaping this space:

- SparkCognition: AI-powered predictive analytics for aerospace.

- Uptake: Machine learning platforms for aviation asset optimization.

- SeerAI: Advanced predictive models for defense and commercial aviation.

- Moogsoft: AI-driven anomaly detection.

- AiRXOS (GE spin-off): Smart maintenance for UAVs and aircraft fleets.

Startups bring flexibility and innovation, filling gaps left by larger OEMs.

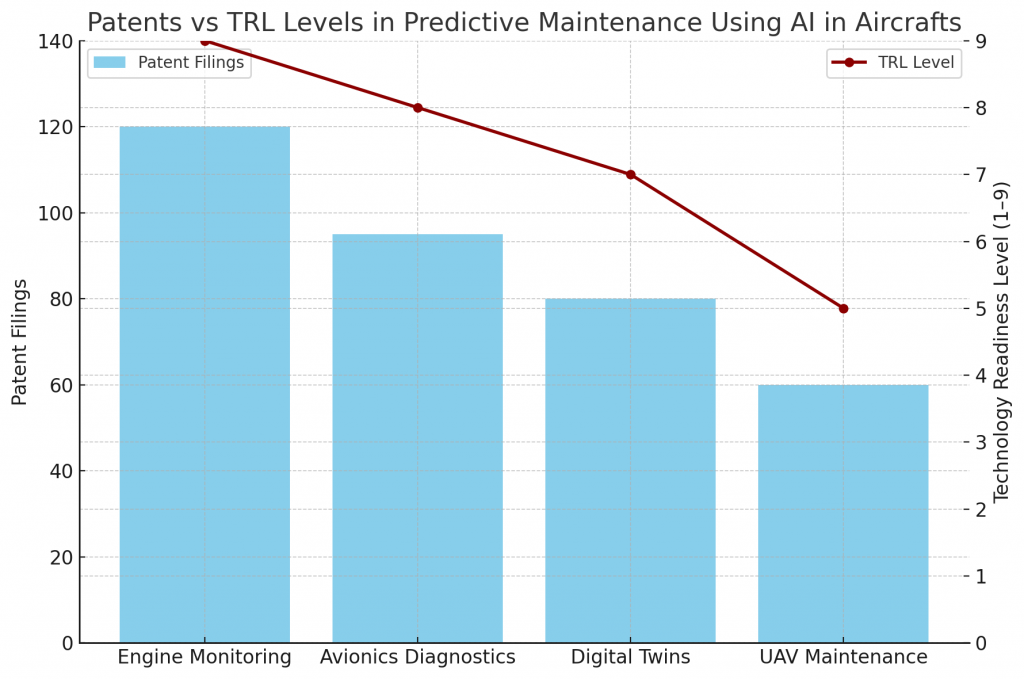

What Do Patents and TRL Levels Indicate?

Patent activity is strong in:

- Sensor integration for aviation systems.

- AI anomaly detection models.

- Digital twin frameworks for predictive analytics.

- Smart maintenance scheduling platforms.

Technology Readiness Levels (TRLs):

- Predictive engine monitoring: TRL 8–9, in full deployment.

- Digital twin simulations: TRL 6–8, under industrial adoption.

- Fleet-wide AI analytics: TRL 7–8, scaling globally.

- UAV predictive maintenance: TRL 4–6, emerging area.

The patent landscape confirms both maturity and rapid growth potential.

What Are the Challenges in Adoption?

Despite its promise, challenges remain:

- High initial investment: Significant costs for AI platforms and sensors.

- Data privacy: Sensitive flight data must be protected.

- Integration: Airlines must align predictive systems with legacy IT.

- Regulation: Aviation authorities require rigorous certification.

- Workforce reskilling: Engineers must adapt to AI-driven workflows.

Overcoming these barriers is key to scaling predictive maintenance using AI in aircrafts globally.

What Is the Future Outlook?

The future of aviation will increasingly depend on AI-powered maintenance:

- Short-term (1–5 years): AI-enabled monitoring systems become mainstream.

- Medium-term (5–10 years): Integration of predictive analytics with fleet management platforms.

- Long-term (10+ years): Fully autonomous predictive ecosystems powered by AI and digital twins.

The ultimate goal is zero unplanned downtime across global aviation fleets.

How Can PatentsKart Help?

PatentsKart provides expert support for innovators in predictive maintenance using AI in aircrafts through:

- Patent landscaping: Identify innovation opportunities.

- Freedom-to-operate studies: Avoid litigation risks.

- Competitor benchmarking: Track leaders and startups.

- TRL benchmarking: Map maturity of predictive technologies.

- Licensing assistance: Accelerate commercialization.

By combining IP insights with technology analysis, PatentsKart empowers aviation innovators to lead the future.

Conclusion

Aviation safety, cost-efficiency, and sustainability are no longer just goals—they are necessities. Predictive maintenance using AI in aircrafts delivers these outcomes by turning raw data into actionable intelligence.

As the industry moves toward smarter fleets, predictive maintenance is emerging as a cornerstone of modern aviation. The airlines that invest today will define tomorrow’s global air transport.

FAQs About Predictive Maintenance Using AI in Aircrafts

Q1. What is predictive maintenance using AI in aircrafts?

It is an AI-driven approach to forecast and prevent failures in aircraft systems.

Q2. Why is it important?

It enhances safety, reduces costs, and minimizes downtime.

Q3. Which companies lead in this space?

Airbus, Boeing, GE Aviation, Rolls-Royce, and Lufthansa Technik.

Q4. What are the challenges?

High costs, integration issues, data privacy, and regulation.

Q5. How can PatentsKart help?

By providing patent insights, competitor analysis, and commercialization strategies.