Climate change has placed carbon dioxide (CO₂) at the center of global concern. Traditionally viewed as waste, CO₂ is now being reimagined as a valuable resource. At the heart of this shift is CO2 conversion into chemicals, a process that captures emissions and transforms them into fuels, polymers, and essential industrial compounds.

By integrating catalytic, electrochemical, and biological pathways, CO2 conversion into chemicals offers a practical approach to reduce greenhouse gases while creating economic value. This dual benefit makes it one of the most promising technologies for building a sustainable and circular economy.

What Is CO2 Conversion into Chemicals?

CO2 conversion into chemicals refers to the set of technologies that transform captured carbon dioxide into valuable chemical products. Unlike traditional processes that emit CO₂, these technologies recycle it as a raw material.

Core methods include:

- Catalytic conversion: Using catalysts to convert CO₂ into fuels or feedstocks.

- Electrochemical processes: Powering CO₂ reactions with renewable electricity.

- Biological pathways: Leveraging microbes and enzymes to synthesize useful chemicals.

- Photocatalysis: Using light energy to drive CO₂ transformations.

This approach converts a climate liability into an industrial asset.

Why Is CO2 Conversion into Chemicals Important?

The importance lies in solving urgent environmental and industrial challenges:

- Climate change mitigation: Reduces atmospheric CO₂ levels.

- Circular economy: Reuses carbon as a feedstock, minimizing waste.

- Energy transition: Creates synthetic fuels compatible with existing systems.

- Economic opportunity: Unlocks new markets for sustainable chemicals.

- Global policy alignment: Supports net-zero and carbon neutrality targets.

In short, CO2 conversion into chemicals offers both ecological and economic benefits.

How Does CO2 Conversion into Chemicals Work?

The process integrates carbon capture with chemical transformation:

- Step 1: Capture: Collect CO₂ from industrial plants or directly from the air.

- Step 2: Activation: Break CO₂’s stable bonds through catalytic or electrochemical processes.

- Step 3: Conversion: Transform activated CO₂ into fuels, plastics, or specialty chemicals.

- Step 4: Utilization: Deploy products in transport, energy, agriculture, and manufacturing.

- Step 5: Recycling loop: Capture emissions again for continuous cycles.

By embedding CO₂ into value chains, CO2 conversion into chemicals closes the carbon loop.

What Are the Benefits of CO2 Conversion into Chemicals?

Key benefits include:

- Environmental sustainability: Cuts greenhouse gas emissions.

- Industrial resilience: Creates alternative feedstocks independent of fossil fuels.

- Job creation: Opens new green technology industries.

- Energy efficiency: Uses renewable energy in conversion processes.

- Global competitiveness: Positions countries at the forefront of green innovation.

For businesses and governments, CO2 conversion into chemicals delivers long-term value.

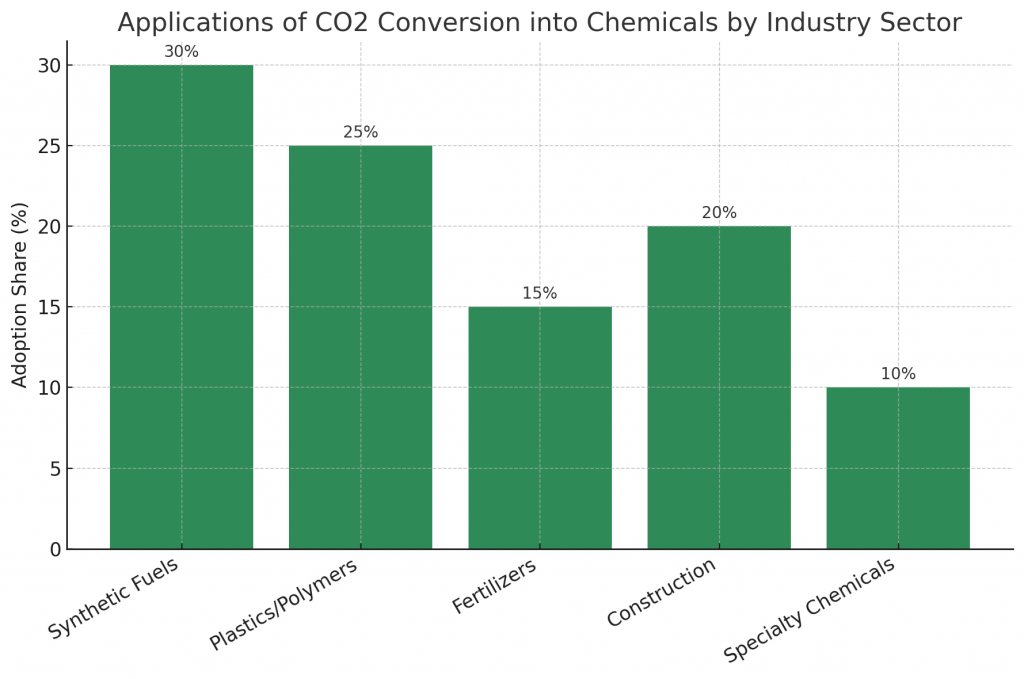

What Are the Applications of CO2 Conversion into Chemicals?

Applications span across industries:

- Synthetic fuels: Methanol, ethanol, and aviation fuels.

- Plastics and polymers: Polycarbonates and biodegradable plastics.

- Fertilizers: Urea and other nitrogen-based products.

- Construction materials: Carbonates and cement additives.

- Specialty chemicals: Fine chemicals for pharmaceuticals and coatings.

These applications prove its relevance across the global economy.

Which Companies Are Leading in CO2 Conversion into Chemicals?

Global corporations are scaling adoption:

- Covestro: Using CO₂ to produce polycarbonates.

- BASF: Developing catalytic pathways for CO₂ conversion.

- LanzaTech: Biological conversion into fuels and chemicals.

- Climeworks: Direct air capture integrated with chemical synthesis.

- ExxonMobil: Research in electrochemical and catalytic solutions.

These leaders validate the commercial promise of CO2 conversion into chemicals.

Which Startups Are Innovating Rapidly?

Startups bring disruptive technologies to market:

- Twelve: Electrochemical CO₂-to-fuels and plastics.

- CarbonCure: Embedding CO₂ in concrete.

- Opus 12 (rebranded as Twelve): Modular CO₂ conversion systems.

- Newlight Technologies: Producing bioplastics from CO₂.

- SkyNano: Nanomaterials synthesized from captured CO₂.

Agility from these startups accelerates the scaling of CO2 conversion into chemicals.

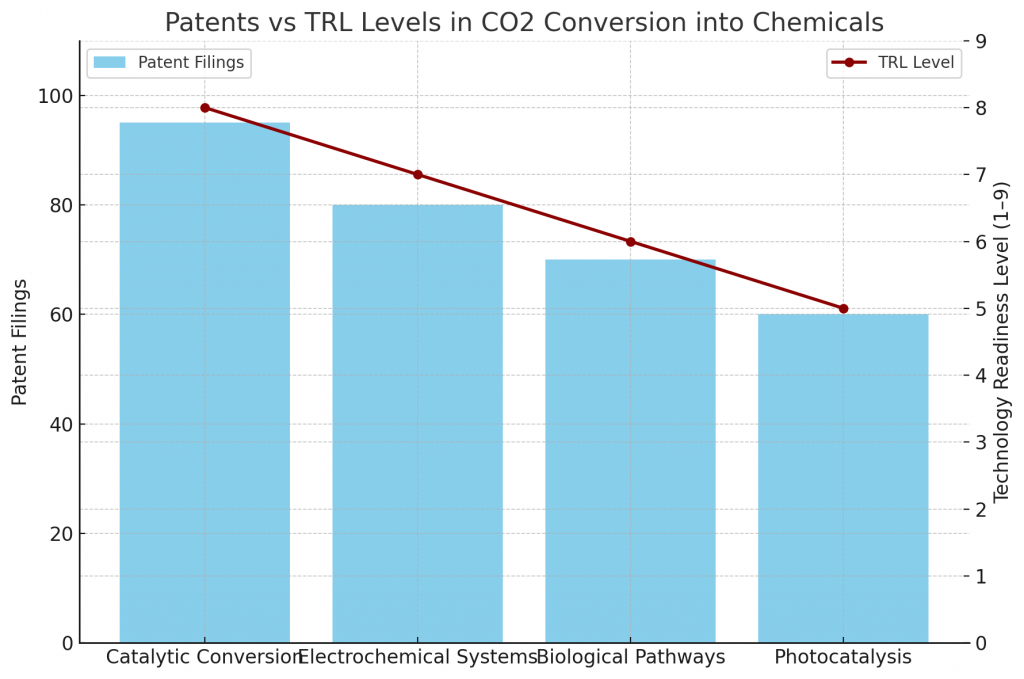

What Do Patents and TRL Levels Indicate?

Patent activity shows strong focus on:

- Electrochemical catalysts.

- Microbial CO₂ conversion.

- Photocatalytic nanomaterials.

- Integration with renewable energy.

Technology Readiness Levels (TRLs):

- Catalytic conversion: TRL 7–9, near commercialization.

- Electrochemical systems: TRL 6–8, scaling pilots.

- Biological pathways: TRL 5–7, growing adoption.

- Photocatalysis: TRL 4–6, early-stage development.

These indicators reveal strong innovation and scaling potential.

What Are the Challenges in Adoption?

Challenges remain:

- High costs: Conversion processes remain energy-intensive.

- Scalability: Pilots need scaling to industrial levels.

- Policy gaps: Global incentives are inconsistent.

- Market readiness: Industries must adapt to new feedstocks.

- Public perception: Education needed on CO₂-derived products.

Addressing these barriers will unlock the full potential of CO2 conversion into chemicals.

What Is the Future Outlook?

The future looks promising:

- Short term (1–5 years): Demonstration plants expand.

- Medium term (5–10 years): Integration with renewable power and industry.

- Long term (10+ years): Widespread adoption in fuels, plastics, and construction.

This confirms that CO2 conversion into chemicals will be central to sustainable industry.

How Can PatentsKart Help?

PatentsKart empowers innovators in CO2 conversion into chemicals with:

- Patent landscaping to identify opportunities.

- Competitor benchmarking to track industry leaders.

- Freedom-to-operate studies to mitigate risks.

- TRL benchmarking to assess maturity.

- Commercialization support to accelerate adoption.

This ensures innovators gain a competitive edge in green chemistry.

Conclusion

The transition to sustainability requires bold innovation. CO2 conversion into chemicals transforms emissions into valuable resources, enabling both decarbonization and economic growth.

As industries and governments seek solutions, this technology offers a pathway to a truly circular and climate-resilient future.

FAQs About CO2 Conversion into Chemicals

Q1. What is CO2 conversion into chemicals?

It is the process of transforming captured CO₂ into fuels, plastics, and industrial chemicals.

Q2. Why is it important?

It reduces emissions while creating valuable products for global industries.

Q3. Which companies are leaders?

Covestro, BASF, LanzaTech, Climeworks, and ExxonMobil.

Q4. What challenges exist?

High costs, scalability issues, and inconsistent policies.

Q5. How can PatentsKart help innovators?

By providing patent analysis, TRL benchmarking, and commercialization support.