The global shift toward sustainable transportation has accelerated the development of advanced electric vehicles (EVs). While batteries and motors receive most of the attention, one often-overlooked component plays a critical role in ensuring smooth, efficient, and reliable performance—bearings in electric vehicles.

From reducing friction to enabling high-speed rotations, bearings in electric vehicles support efficiency, durability, and long-term reliability of drivetrains, motors, and auxiliary systems. Their design and innovation are central to making EVs more competitive and sustainable.

What Are Bearings in Electric Vehicles?

Bearings in electric vehicles are precision-engineered components that minimize friction and support rotational or linear movement in EV systems.

Key types include:

- Deep groove ball bearings: Widely used for high-speed EV motors.

- Cylindrical roller bearings: Handle heavy radial loads in drivetrains.

- Ceramic hybrid bearings: Offer reduced friction and higher durability.

- Tapered roller bearings: Suitable for e-axles and wheel hubs.

- Sensor-integrated bearings: Enable predictive maintenance.

These bearings ensure that EV systems operate with minimal energy loss and maximum efficiency.

Why Are Bearings in Electric Vehicles Important?

The importance of bearings in electric vehicles is tied to performance, efficiency, and durability:

- Energy efficiency: Reduce friction, improving battery range.

- High-speed reliability: Handle motor speeds up to 20,000 RPM.

- Durability: Support long life cycles under variable loads.

- Thermal stability: Operate efficiently under high temperatures.

- Noise reduction: Enhance passenger comfort in quieter EV cabins.

This makes them indispensable to the success of electric mobility.

How Do Bearings in Electric Vehicles Work?

The working principle of bearings in electric vehicles involves reducing friction between moving parts:

- Step 1: Load support – Bearings carry radial and axial loads from rotating components.

- Step 2: Motion facilitation – Balls or rollers enable smooth rotation.

- Step 3: Friction reduction – Minimize energy loss during operation.

- Step 4: Heat dissipation – Advanced materials maintain thermal balance.

- Step 5: Integration with sensors – Predictive maintenance enhances performance.

This functionality directly impacts efficiency and EV range.

What Are the Benefits of Bearings in Electric Vehicles?

The benefits of bearings in electric vehicles include:

- Extended range: Less energy wasted through friction.

- Reduced maintenance: Advanced coatings and materials last longer.

- High-speed capability: Optimized for powerful EV motors.

- Sustainability: Lower energy loss supports greener driving.

- Reliability: Enhanced durability ensures consistent performance.

These advantages make bearings critical to EV innovation.

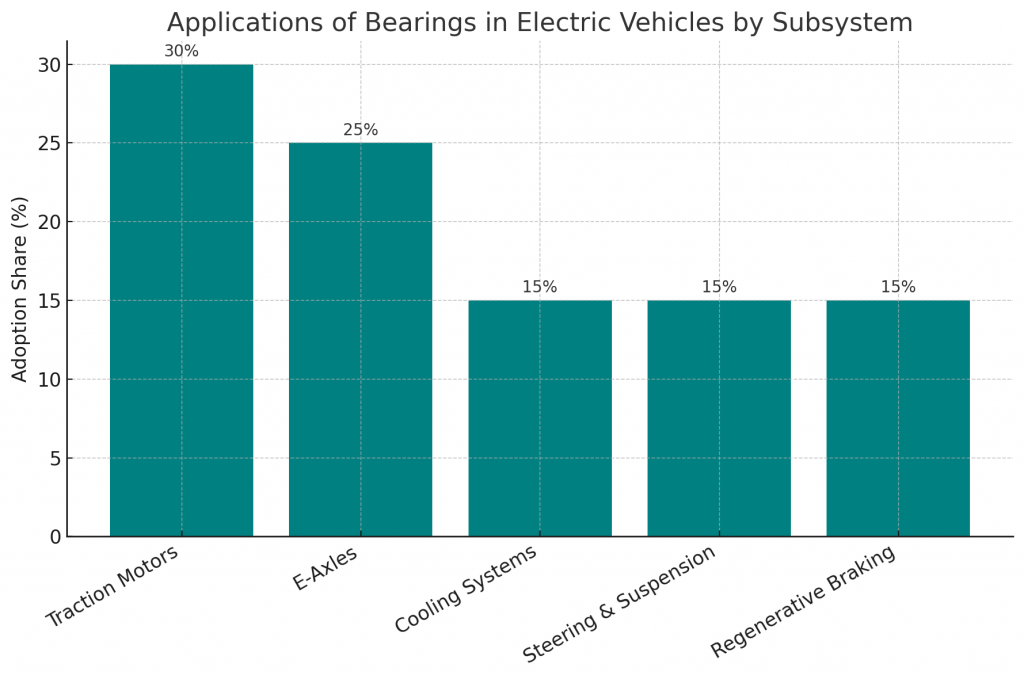

What Are the Applications of Bearings in Electric Vehicles?

Applications cover multiple EV subsystems:

- Traction motors: Deep groove and hybrid bearings for efficiency.

- E-axles: Tapered and cylindrical roller bearings.

- Battery cooling systems: Bearings in pumps and compressors.

- Steering and suspension: Precision bearings for maneuverability.

- Regenerative braking systems: Bearings to handle high torque.

This wide usage underscores their importance across EV architectures.

Which Companies Are Leading in Bearings in Electric Vehicles?

Several corporations are at the forefront:

- SKF: Ceramic hybrid and sensor-integrated EV bearings.

- NSK Ltd.: Bearings for ultra-high-speed electric motors.

- NTN Corporation: E-axle and wheel hub bearing solutions.

- Schaeffler Group: Thermal management and e-mobility bearings.

- JTEKT Corporation: Advanced materials for EV drivetrain bearings.

These leaders are setting benchmarks in the field of bearings in electric vehicles.

Which Startups Are Innovating Rapidly?

Startups are driving disruptive innovations:

- Hybrid Bearing Solutions: Developing custom EV-focused bearings.

- CooSpace: Friction-reduction technologies in bearing designs.

- Advanced Tribology Systems: Coatings for longer bearing life.

- SpinTech Bearings: Sensor-embedded smart bearings.

- GreenMotion Bearings: Sustainable manufacturing methods.

These players add agility and innovation to the global EV ecosystem.

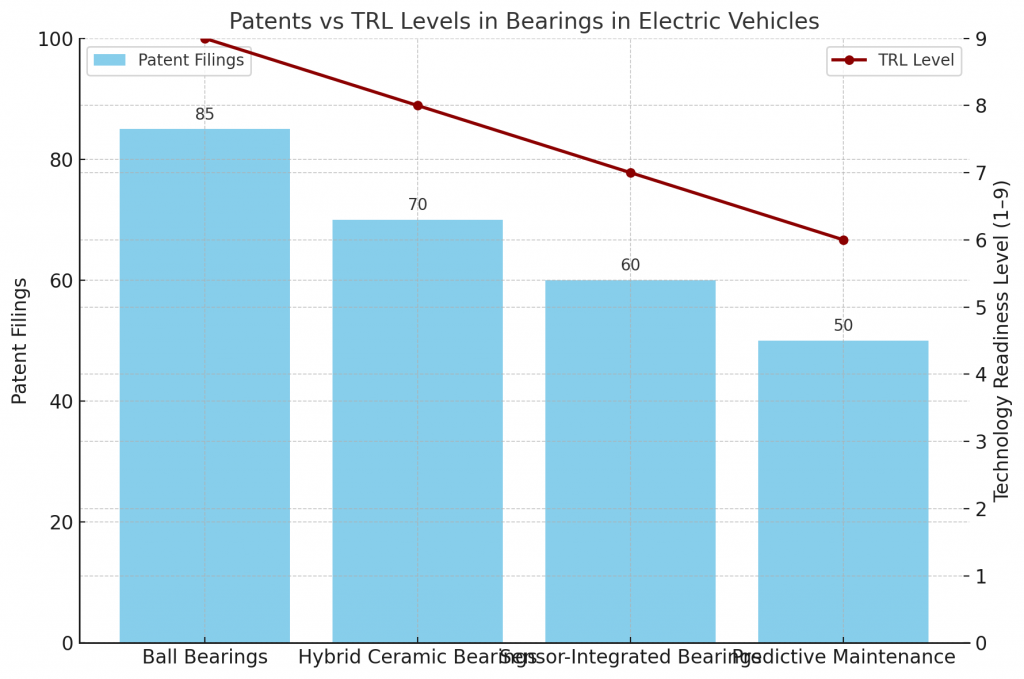

What Do Patents and TRL Levels Indicate?

Patent activity focuses on:

- Ceramic hybrid technologies.

- Sensor-embedded bearing designs.

- Low-friction coatings.

- High-speed motor integration.

Technology Readiness Levels (TRLs):

- Deep groove ball bearings: TRL 9, widely commercialized.

- Hybrid ceramic bearings: TRL 7–9, scaling fast.

- Sensor-integrated designs: TRL 6–8, pilot programs.

- Predictive maintenance integration: TRL 5–7, experimental stages.

This balance reflects maturity with ongoing innovation.

What Are the Challenges in Adoption?

Challenges include:

- Cost: Advanced ceramic bearings are expensive.

- Material supply: Rare ceramics face sourcing issues.

- Durability under extreme loads: High torque stresses EV bearings.

- Thermal management: Requires advanced cooling solutions.

- Integration complexity: Sensor-enabled bearings need standardization.

These barriers must be addressed for wider adoption of bearings in electric vehicles.

What Is the Future Outlook?

The future outlook for bearings in electric vehicles includes:

- Short term (1–5 years): Growth of ceramic hybrid solutions.

- Medium term (5–10 years): Widespread sensor integration.

- Long term (10+ years): AI-driven predictive maintenance systems.

This confirms bearings as an integral part of EV innovation.

How Can PatentsKart Help?

PatentsKart supports innovators in bearings in electric vehicles with:

- Patent landscaping to uncover white space.

- Competitor analysis to track leaders.

- TRL benchmarking to measure technology maturity.

- Freedom-to-operate studies to avoid risks.

- Commercialization strategies to scale globally.

This ensures stakeholders stay ahead in the EV ecosystem.

Conclusion

The success of electric mobility depends not only on batteries and motors but also on the smaller components that drive efficiency. Bearings in electric vehicles play a crucial role in enhancing performance, ensuring durability, and enabling sustainability.

As EV adoption accelerates, innovations in bearing design will define the future of mobility.

FAQs About Bearings in Electric Vehicles

Q1. What are bearings in electric vehicles?

They are precision components that reduce friction and support movement in EV systems.

Q2. Why are they important?

They extend range, enhance efficiency, and ensure durability.

Q3. Which companies lead in EV bearings?

SKF, NSK, NTN, Schaeffler, and JTEKT Corporation.

Q4. What challenges exist in adoption?

High costs, material supply issues, and integration complexity.

Q5. How can PatentsKart help innovators?

By offering patent insights, TRL benchmarking, and commercialization support.