What is Nano-Porous Polyethylene and why does it matter?

The materials world is changing fast, and decision-makers want comfort, performance, and low impact in the same package. Nano-Porous Polyethylene delivers exactly that. Built with nanoscale pores inside a polyethylene matrix, it lets heat and water vapor pass while staying strong, light, and recyclable.

Traditional fabrics and films trap warmth, cause sweat buildup, and complicate recycling. By contrast, Nano-Porous Polyethylene moves heat away from the body, keeps moisture balanced, and reduces weight without sacrificing durability. Those qualities make it attractive to apparel, healthcare, food, logistics, and energy players who need reliable performance with a smaller footprint.

In practice, Nano-Porous Polyethylene can cut cooling demand in hot environments, extend shelf life for delicate goods, and improve comfort in demanding jobs. It achieves all of this through precise pore engineering, consistent processing, and compatibility with mainstream manufacturing methods.

How does Nano-Porous Polyethylene work in textiles?

Adoption of Nano-Porous Polyethylene in apparel is accelerating because it solves real, everyday problems for people who work, train, and travel in heat.

- Thermal regulation: Nanoscale pores allow infrared radiation to escape, preventing heat buildup under layers.

- Moisture control: Water vapor moves outward while liquid sweat is resisted, improving comfort during exertion.

- Strength with softness: Fibers and membranes remain light yet durable, suitable for uniforms and sportswear.

- Cleaner end-of-life: Compared with multi-material blends, Nano-Porous Polyethylene simplifies recycling.

Teams exploring NanoPE Technology report consistent wearer comfort in warm climates and lower odor retention in active garments. That’s why interest in Nano-Porous Polyethylene in Textiles is rising among performance brands and healthcare providers alike.

How is Nano-Porous Polyethylene used in packaging?

Where temperature swings and moisture matter, Nano-Porous Polyethylene offers clear advantages over conventional films.

- Heat management: Controlled dissipation limits condensation and reduces cold-chain strain.

- Selective barriers: Microbe, dust, and gas control help extend freshness windows for food and pharma.

- Lightweight protection: Strength at low basis weight cuts transport costs and material usage.

- Mono-material circularity: Compared with multilayer laminates, Nano-Porous Polyethylene Packaging improves recyclability.

Producers piloting Nano-Porous Polyethylene report fewer returns linked to spoilage and better performance in humid regions. As regulations favor circular solutions, demand for Nano-Porous Polyethylene packaging formats is set to rise.

Which companies are leading in Nano-Porous Polyethylene?

Global materials leaders and converters are investing to scale Nano-Porous Polyethylene. Programs span breathable apparel membranes, high-barrier wraps, and protective healthcare products.

- DuPont – protective materials and specialty fabrics

- Toray Industries – breathable membranes for apparel systems

- 3M – advanced films for industrial and healthcare use

- BASF – packaging chemistries with lower environmental impact

- Mitsui Chemicals – oxygen-scavenging and barrier films

- Berry Global – lightweight flexible packaging

- Kimberly-Clark – hygiene and medical solutions

Collectively, these players advance NanoPE Technology with pilot lines, co-development with brands, and targeted acquisitions.

What startups are innovating in this space?

A wave of startups is pushing NanoPE Applications into niches where legacy materials underperform.

- Modern Meadow – bio-fabricated materials targeting breathable, durable textiles

- Pangaia – tech-enabled apparel built for comfort and circularity

- TIPA – compostable films with engineered porosity

- Xampla and Notpla – plant-based alternatives inspired by natural polymers

- SRTX and Nano-tex – performance layers focused on comfort and protection

These innovators complement enterprise efforts by experimenting quickly, validating use cases, and informing design guidelines for Nano-Porous Polyethylene.

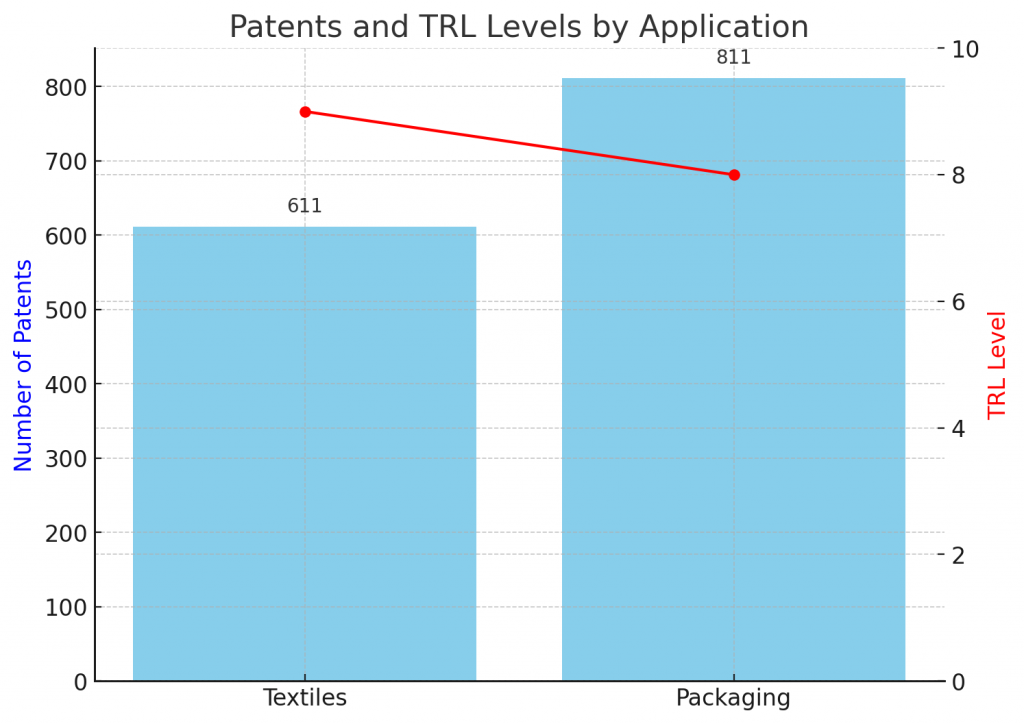

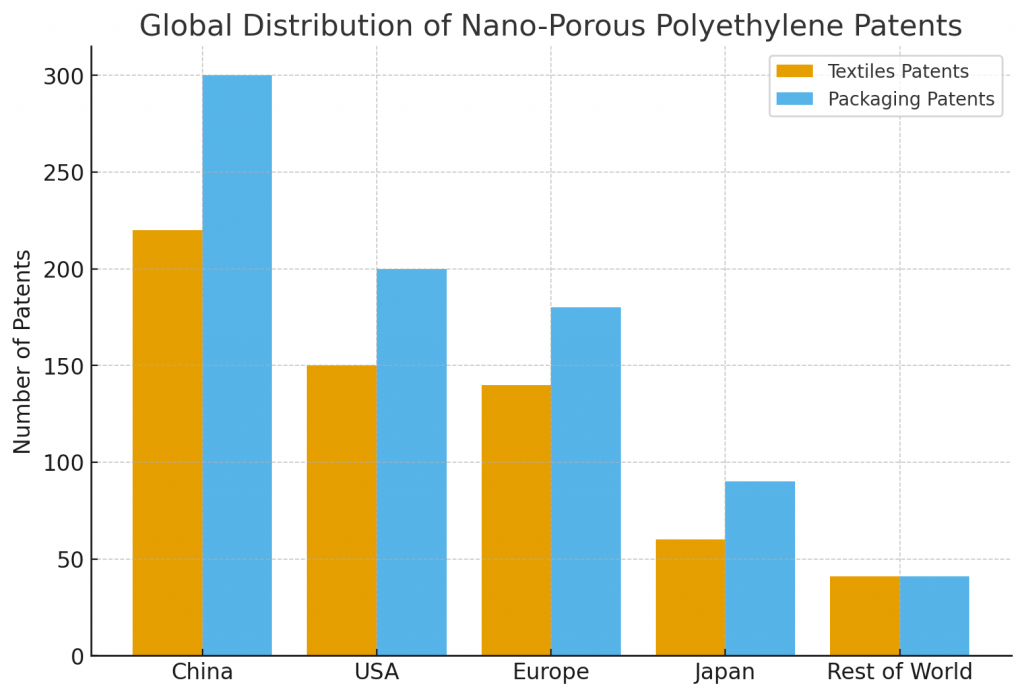

What patents and TRL levels shape adoption?

Market readiness for Nano-Porous Polyethylene can be tracked through intellectual property and technology readiness levels.

- Textiles: mature deployments supported by extensive filings, global jurisdictions, and long vintage years

- Packaging: late-stage development with robust patent growth and clear commercialization paths

Patent families concentrate on pore size control, breathable barrier stacks, antimicrobial finishes, and recyclability. As filings expand, freedom-to-operate analysis becomes essential for brands planning to scale with Nano-Porous Polyethylene.

What are the most valuable applications today?

The versatility of Nano-Porous Polyethylene enables targeted wins where heat, moisture, and hygiene intersect.

- Apparel: activewear, uniforms, medical gowns, outdoor layers

- Packaging: fresh produce, specialty foods, pharma vials, e-commerce mailers

- Healthcare: wound dressings, breathable PPE, implant interfaces

- Energy: battery separators and specialty membranes

- Environment: water harvesting meshes and oil remediation tools

- Agriculture: mulch films and controlled-release coatings

Each use case benefits from engineered porosity plus stable mechanical performance, making Nano-Porous Polyethylene a practical platform for design teams.

Which industries benefit most from this material?

Sectors that balance performance with sustainability see the fastest returns from Nano-Porous Polyethylene.

- Fashion & sportswear: cooler garments, fewer layers, better comfort

- Food & beverage: longer freshness windows with simpler recycling

- Healthcare: safer, breathable protection for clinicians and patients

- Electronics & EVs: membranes that manage heat and moisture

- Agriculture: films that reduce chemical waste and water loss

For operations leaders, the draw is consistent quality at lower weight; for sustainability teams, the appeal is circular design aligned with regulation.

What challenges should teams expect when adopting it?

Three categories dominate implementation risk for Nano-Porous Polyethylene: cost, consistency, and compliance.

- Cost: unit pricing can exceed legacy films or fabrics until scale improves

- Consistency: maintaining uniform pore distribution at throughput is non-trivial

- Compliance: food and medical uses require rigorous validation

Mitigations include co-developing with suppliers, specifying measurable pore metrics, and staging regulatory work early. When executed well, programs with Nano-Porous Polyethylene clear pilots and move to roll-to-roll production.

What does the future outlook look like for this technology?

The medium-term roadmap for Nano-Porous Polyethylene points to broader availability, smarter functionality, and deeper integration with digital systems.

- 1–3 years: passive cooling textiles, mono-material packaging lines, clearer recycling streams

- 3–5 years: responsive pores, hybrid composites, sensor-ready labels

- 5–10 years: self-healing barriers, medical interfaces, advanced energy membranes

As standards evolve and data transparency improves, customers will treat Nano-Porous Polyethylene not as a novelty but as a dependable material class.

How can PatentsKart help with Nano-Porous Polyethylene strategy?

PatentsKart supports executives, IP teams, and product leaders who want results with Nano-Porous Polyethylene and minimal risk.

- Patent landscape analysis: identify white space and benchmark competitors

- Freedom-to-operate: de-risk launches across priority markets

- Competitive intelligence: track filings, TRL signals, and partnerships

- Technology roadmapping: align materials choices with cost and sustainability targets

- Deal support: licensing, JV structures, and supplier diligence

With tailored research and actionable recommendations, we help teams move from pilot to scale confidently.

Conclusion

Nano-Porous Polyethylene is not just a novel material; it is a practical answer to heat, moisture, and recyclability challenges across multiple industries. By pairing engineered porosity with reliable mechanics, it enables cooler clothing, longer-lasting goods, and lighter packaging—while supporting circular design.

Organizations that move early can capture performance gains and regulatory advantages. With the right partners and an informed IP strategy, Nano-Porous Polyethylene becomes a durable competitive edge rather than a lab curiosity.

FAQs

Q1. What is Nano-Porous Polyethylene in simple terms?

It is polyethylene engineered with nanoscale pores so heat and vapor pass while the structure stays strong and light.

Q2. How does it improve apparel performance?

By enabling radiative cooling and moisture transport, garments need fewer heavy layers and remain comfortable during activity.

Q3. Why is it different for packaging?

Selective barriers and heat management extend freshness while mono-material design aids recycling.

Q4. Which teams should evaluate it first?

Apparel developers, cold-chain packaging leads, medical device engineers, and sustainability officers see the quickest wins.

Q5. What role does intellectual property play?

IP determines where you can launch, how to avoid conflicts, and where to invest. A clear view of patents and standards de-risks adoption.