What are self healing materials and why are they important today?

Industries that depend on durability, safety, and uptime are rethinking material choices. From infrastructure and transportation to consumer electronics and medical devices, maintenance costs and failure risks are pushing teams to adopt responsive, design-led approaches. At the center of this shift are self healing materials, engineered systems that can sense damage and autonomously repair or restore function without external intervention.

Unlike traditional polymers and composites that degrade irreversibly, self healing materials aim to extend service life, preserve performance, and reduce waste. They do this through chemistries and architectures that trigger when cracks form, when heat builds, or when moisture changes. In practice, this means fewer catastrophic failures, less downtime, and a measurable improvement in sustainability metrics.

How do these materials actually heal themselves in practice?

Researchers deploy several mechanisms to enable repair:

- Microcapsule networks: Encapsulated agents rupture on crack formation, wetting the interface and rebonding the fracture plane.

- Vascular channels: 3D networks deliver healing monomers repeatedly, allowing multi-cycle repair.

- Dynamic covalent bonds: Reversible chemistries swap partners under heat or light, knitting the matrix back together.

- Supramolecular interactions: Hydrogen bonding and metal–ligand coordination create reversible, on-demand cohesion.

- Shape-memory frameworks: Thermal or electrical stimuli drive crack closure prior to rebonding.

These strategies let self healing materials recover stiffness, toughness, or conductivity after damage, often within minutes to hours.

Where are the highest-impact applications emerging now?

Adoption clusters where maintenance is costly and reliability is non-negotiable. Leading use cases include:

- Aerospace & defense: Coatings and composites that resist FOD and microcracking in extreme environments.

- Automotive & mobility: Paints, elastomers, and battery components that tolerate vibration and thermal cycling.

- Civil infrastructure: Sealants and cementitious systems that slow corrosion and extend bridge and roadway life.

- Electronics: Stretchable conductors and encapsulants that restore function after flex or cut events.

- Medical & wearables: Hydrogels and soft robotics that heal after strain, improving comfort and uptime.

Across these domains, self healing materials shift budgets from reactive repair to designed-in resilience.

Why do operations leaders and sustainability teams care now?

Three forces converge: performance, cost, and climate accountability. The ability of self healing materials to extend asset life improves total cost of ownership and reduces spare-part inventory. At the same time, avoiding premature replacement cuts embodied carbon and waste generation. For regulated sectors, the combination of reliability data and lifecycle assessments supports compliance and brand claims.

Which companies are advancing the field with commercial products?

Large materials innovators and agile startups are both active:

- BASF — Polymer platforms with reversible bonding and adaptive coatings.

- 3M — Protective films and sealants targeting automotive and electronics.

- DuPont — Elastomers and encapsulants for harsh environments.

- Covestro — Polyurethane systems with dynamic crosslinks.

- Arkema — Specialty resins and adhesives with vitrimer behavior.

- Autonomic Materials — Microcapsule-based coatings for corrosion control.

- Adaptive Surface Technologies — Slippery, damage-tolerant coatings.

- LiqCreate / Formlabs ecosystem — Printable resins with repairable networks.

These players translate lab breakthroughs into consistent, spec-driven offerings that help self healing materials reach scale.

Which startups are worth watching for disruptive ideas?

- Intrinsic Materials — Reprocessable elastomers for mobility.

- SelfAssemblyLab — Programmable matter and responsive fabrication.

- Tiamat — Polymer electrolytes exploring autonomous repair.

- Lattice Automation partners — AI-guided polymer design workflows.

- Vitrimer-focused ventures — Networks that relax and rebond under heat.

The common thread: rapid iteration with customers, pilot-line proof, and IP around chemistry plus process—an approach well suited to self healing materials.

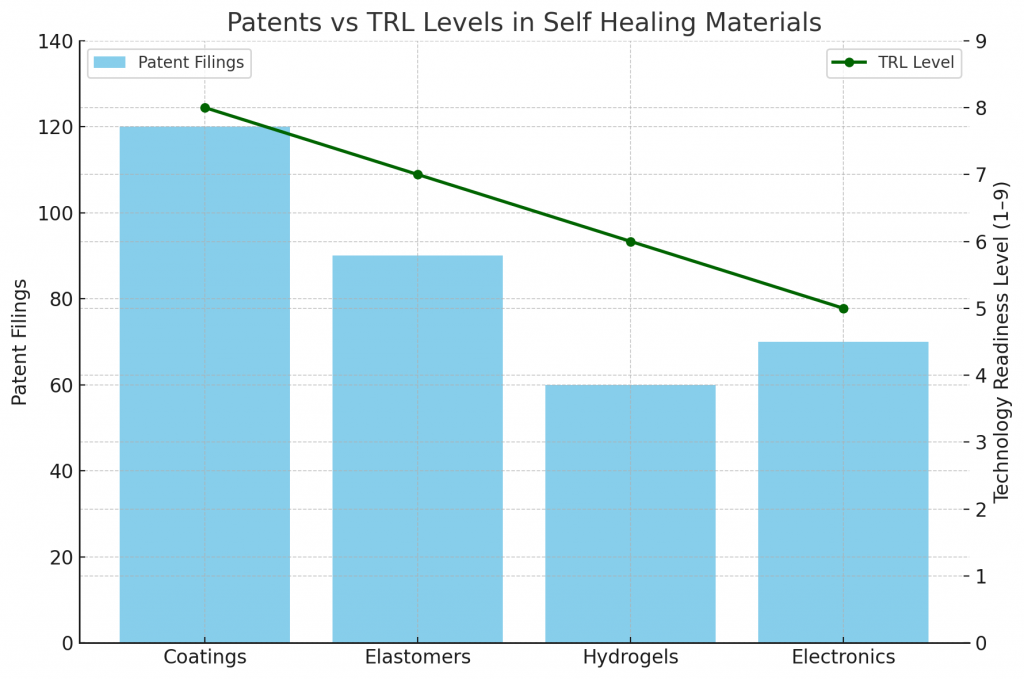

What do patent trends and TRL levels say about maturity?

Patent families are densest around microencapsulation, dynamic covalent networks, and conductive composites. A simplified TRL snapshot looks like this:

- Coatings for corrosion & scratch repair: TRL 7–9 in industrial settings.

- Elastomers for mobility and seals: TRL 6–8 with fleet pilots.

- Hydrogels for medical use: TRL 5–7 pending regulatory pathways.

- Electronic conductors & dielectrics: TRL 4–6 in lab-to-pilot transition.

In aggregate, filings and demonstrators indicate that self healing materials are moving from single-use demos to multi-cycle reliability under service conditions.

What are the hard problems engineers still need to solve?

- Validation speed: Proving multi-cycle healing under real loads takes time.

- Compatibility: Additives must not compromise baseline mechanicals or EHS requirements.

- Trigger control: Heals should activate under damage, not during normal operation.

- Cost & scalability: Microcapsules and vascular scaffolds add processing steps.

- Standardization: Test methods and benchmarks are still converging.

Addressing these gaps will help self healing materials become default choices rather than specialty options.

How should teams evaluate economics and pick the right use case first?

Start with a single metric that matters most—dollars per avoided failure, warranty return rate, or mean time between service. Map that metric to a pilot part where damage is frequent and costly. Then:

- Quantify baseline failure modes and intervals.

- Select a healing mechanism matched to trigger and environment.

- Run statistically robust A/B trials at service conditions.

- Track recovery of modulus, adhesion, or conductivity over cycles.

- Build a supplier QA plan and change-control process.

This pragmatic pathway keeps self healing materials grounded in measurable value.

How do these materials support sustainability and regulatory goals?

When products last longer and avoid premature replacement, embedded emissions drop. Many systems in self healing materials are also reprocessable, enabling repair plus circularity. For regulated spaces such as transport and medical, supplier documentation, chemical disclosure, and third-party verification are essential. Teams that plan compliance early reduce delays and protect claims.

What does the next decade look like for this technology class?

Expect rapid growth in multi-heal systems, vitrimer-based networks, and conductive composites for flexible electronics. Digital design of experiments and robotic testing will shorten development cycles. Supply chains will regionalize for resilience, with specialized mixers, capsule formers, and additive packages available off the shelf. As benchmarks converge, self healing materials will move from eye-catching demos to quiet, ubiquitous reliability features.

Which regions and partnerships are accelerating adoption?

North America focuses on aerospace, defense, and high-value infrastructure, while Europe emphasizes circularity and stringent compliance in coatings and transport. Asia scales manufacturing at speed, supplying additives, capsule systems, and mixers for global programs. Cross-border consortia fund pre-competitive data on fatigue, adhesion, and weathering so buyers can compare options side by side. This coordination lowers risk and makes it easier to specify self healing materials in long-lived assets.

What real-world case studies illustrate measurable value?

- Bridge deck sealants: Field pilots showed crack sealing within hours, deferring resurfacing by multiple seasons.

- Battery pack gasketing: Elastomers recovered compression set after heat excursions, maintaining ingress protection.

- Consumer scratch coats: Automotive clearcoats hid micro-marring, preserving gloss between scheduled details.

- Stretchable circuits: Conductive inks restored pathways after cuts, keeping wearables online during training.

Each case links improved uptime to lower service cost—core to the business case for self healing materials.

How can engineers design healing into parts from day one?

A practical checklist keeps teams on track:

- Confirm where and how damage initiates under real loads.

- Match the healing trigger to that damage mode and environment.

- Co-design geometry so cracks close before chemistry cures.

- Select additives that meet EHS and flammability limits.

- Build test matrices that prove repeatability across cycles and climates.

By tying trigger, transport, and rebonding together, designers turn self healing materials from lab novelty into dependable product features.

How should risks and regulatory questions be managed proactively?

Document material identity, migration limits, and end-of-life options early. For transport, align with relevant fire, smoke, and toxicity standards; for medical, plan biocompatibility and sterilization pathways. Establish change control with suppliers so reformulations are traceable. Finally, publish clear care instructions so performance claims match field reality—a discipline that helps self healing materials earn buyer trust.

How can PatentsKart help organizations win with this technology?

PatentsKart supports R&D, product, and IP leaders with decision-grade intelligence:

- Patent landscapes and white-space maps to focus investment.

- Freedom-to-operate reviews across target geographies.

- Competitor and startup tracking to spot partnerships or threats.

- TRL-aligned roadmaps that connect lab milestones to commercial gates.

- Licensing and deal support for scale-up and market entry.

With this support, teams reduce risk and speed time to value when adopting self healing materials.

Conclusion

As product lifecycles compress and reliability expectations rise, the ability to design for repair at the molecular and architectural level becomes a strategic advantage. By combining the right healing mechanism with rigorous validation, companies can ship parts that endure real-world abuse and keep performing. With clear metrics, strong supplier programs, and smart IP strategy, self healing materials will underpin the next era of resilient products.

FAQs

Q1. What are the simplest words to describe this class of materials?

They are engineered systems that can detect damage and restore function without external service calls—an ability that sets self healing materials apart from conventional options.

Q2. Where do they deliver the fastest ROI?

High-wear parts in mobility, industrial coatings that prevent corrosion callouts, and flexible electronics exposed to repeated strain.

Q3. How many times can a part heal?

It depends on the mechanism: microcapsules often heal once per site, while vascular and dynamic networks can recover repeatedly when designed correctly.

Q4. Do these materials complicate recycling or compliance?

Not when designed with disclosure and end-of-life in mind; many systems are reprocessable, and suppliers provide data packages for audits.

Q5. How can PatentsKart reduce risk on a first program?

We map the IP landscape, screen suppliers, and define test plans so your pilot validates quickly and scales smoothly.