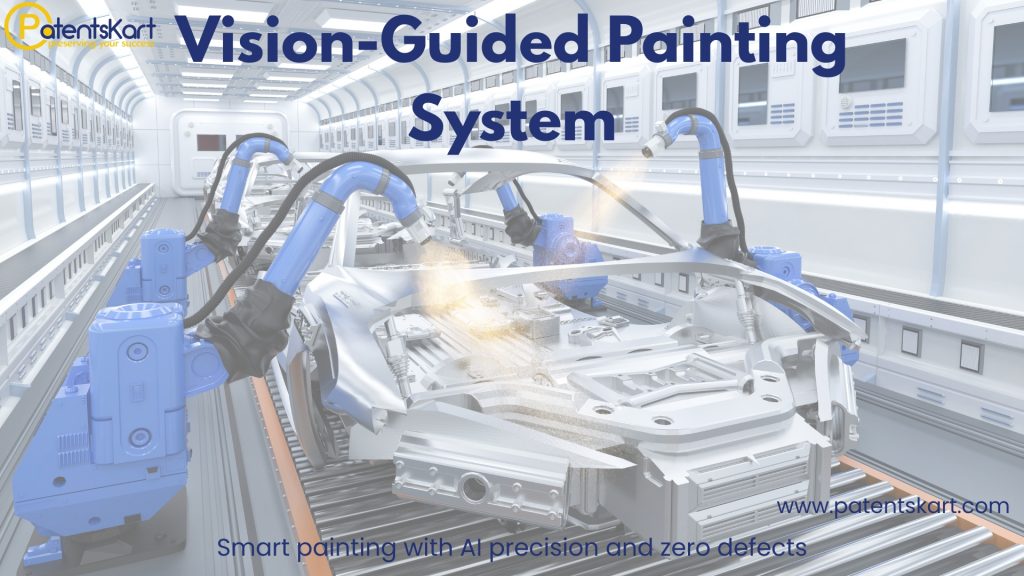

Industrial painting is one of the most critical finishing processes in manufacturing. From automobiles to aerospace components and heavy machinery, painting ensures durability, aesthetics, and protection from corrosion. Traditional manual painting, however, comes with challenges—uneven coating, high labor dependency, safety hazards, and rising costs. Automation started addressing some of these issues, but precision and adaptability were limited until vision systems came into play. Today, the vision-guided painting system is redefining how factories achieve accuracy, efficiency, and consistency in painting operations.

By combining robotics with artificial intelligence and advanced imaging, a vision-guided painting system offers manufacturers a way to automate coating processes with unmatched precision. Whether in automotive plants or consumer goods industries, this innovation is rapidly becoming a cornerstone of smart manufacturing.

What Is a Vision-Guided Painting System?

A vision-guided painting system is a robotic painting setup equipped with cameras and AI-based image processing. Instead of following fixed pre-programmed paths, the system uses real-time vision data to adapt to different part shapes, orientations, and positions.

Key components include:

- Industrial robots: Carry out spray painting tasks.

- Vision sensors and cameras: Capture part dimensions, angles, and surfaces.

- AI vision systems: Process data and guide robotic arms dynamically.

- Control software: Synchronizes painting speed, angles, and spray patterns.

This system integrates industrial robotics and AI vision systems to deliver adaptive automation for precision coating.

Why Is a Vision-Guided Painting System Important?

Factories deal with constant variations in part shapes, batch sizes, and surface complexities. A vision-guided painting system is important because it solves three pressing issues:

- Precision coating: Delivers uniform paint application with reduced overspray.

- Flexibility: Adjusts to part variations without lengthy reprogramming.

- Cost efficiency: Reduces paint waste, labor costs, and rework.

- Workplace safety: Minimizes human exposure to hazardous environments.

- Sustainability: Optimizes material usage for eco-friendly operations.

For industries adopting smart manufacturing, this system ensures competitiveness and long-term resilience.

How Does a Vision-Guided Painting System Work?

The process involves several coordinated steps:

- Step 1: Scanning – Cameras capture 2D/3D images of the workpiece.

- Step 2: Processing – AI algorithms analyze geometry, detect edges, and identify painting zones.

- Step 3: Path generation – The system calculates optimized spray paths.

- Step 4: Robotic execution – The robotic arm paints while adapting in real time.

- Step 5: Quality monitoring – Vision feedback ensures consistent thickness and finish.

This closed-loop operation makes a vision-guided painting system more accurate than fixed-path robotic painting.

What Are the Benefits of a Vision-Guided Painting System?

Benefits extend across production quality, efficiency, and sustainability:

- Improved coating quality: Reduces defects and ensures uniform finish.

- Reduced material usage: Optimizes spray angles and flow.

- Adaptability: Handles diverse parts without downtime.

- Lower operational costs: Cuts rework and paint waste.

- Enhanced worker safety: Limits human exposure to fumes.

These benefits make automated painting more than a cost-saving measure—it becomes a driver of pharmaceutical innovation in coating and finishing technologies.

What Are the Applications of Vision-Guided Painting Systems?

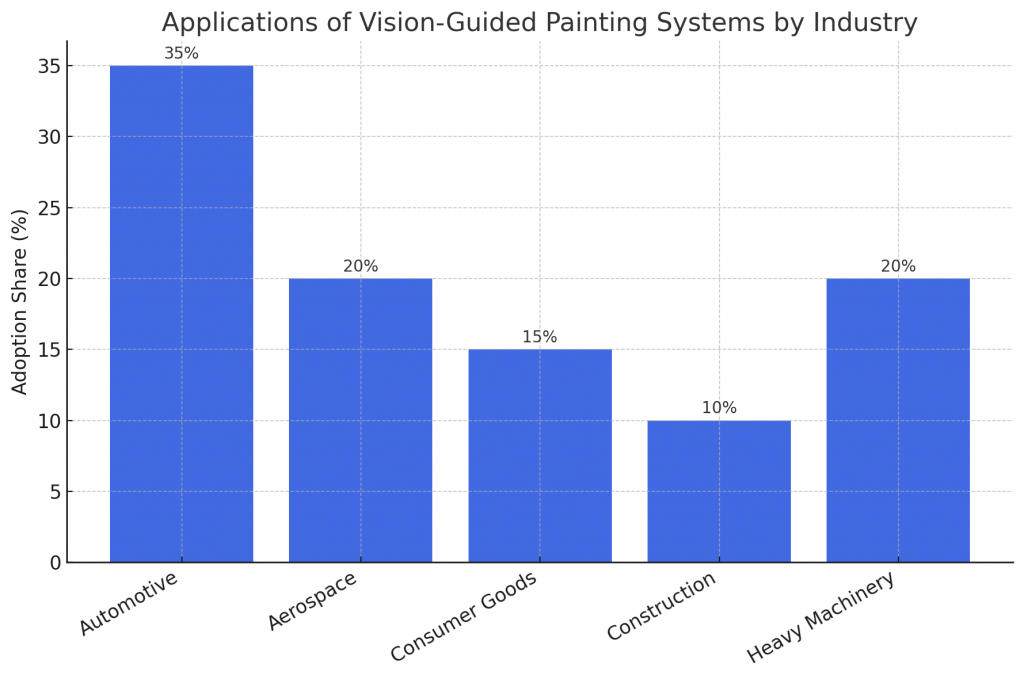

Applications span multiple industries:

- Automotive: Painting car bodies, bumpers, and custom parts.

- Aerospace: Coating aircraft parts with precision.

- Consumer goods: Painting furniture, appliances, and electronics.

- Construction: Protective coating for structural steel.

- Heavy machinery: Durable coatings for industrial equipment.

Every application shows how a vision-guided painting system improves efficiency while maintaining high-quality finishes.

Which Companies Are Leading in Vision-Guided Painting Systems?

Several corporations are at the forefront:

- ABB Robotics: Advanced robotic painting with vision integration.

- FANUC: Robotic painting solutions with smart vision systems.

- KUKA: Offering AI-enabled robotic painting automation.

- Yaskawa Motoman: Specializes in precision coating robotics.

- Dürr Systems: Known for eco-efficient painting automation.

These players highlight the strategic importance of vision-guided painting system technology in modern factories.

Which Startups Are Innovating?

- Realtime Robotics: AI-based motion planning for industrial robots.

- OptoForce (OnRobot): Tactile and vision sensors for adaptive automation.

- Scape Technologies: Specializes in machine vision for robots.

- Ready Robotics: Simplifying programming of robotic systems.

- Path Robotics: AI-driven autonomous welding and painting solutions.

Startups are making precision coating technology more accessible for small and mid-sized manufacturers.

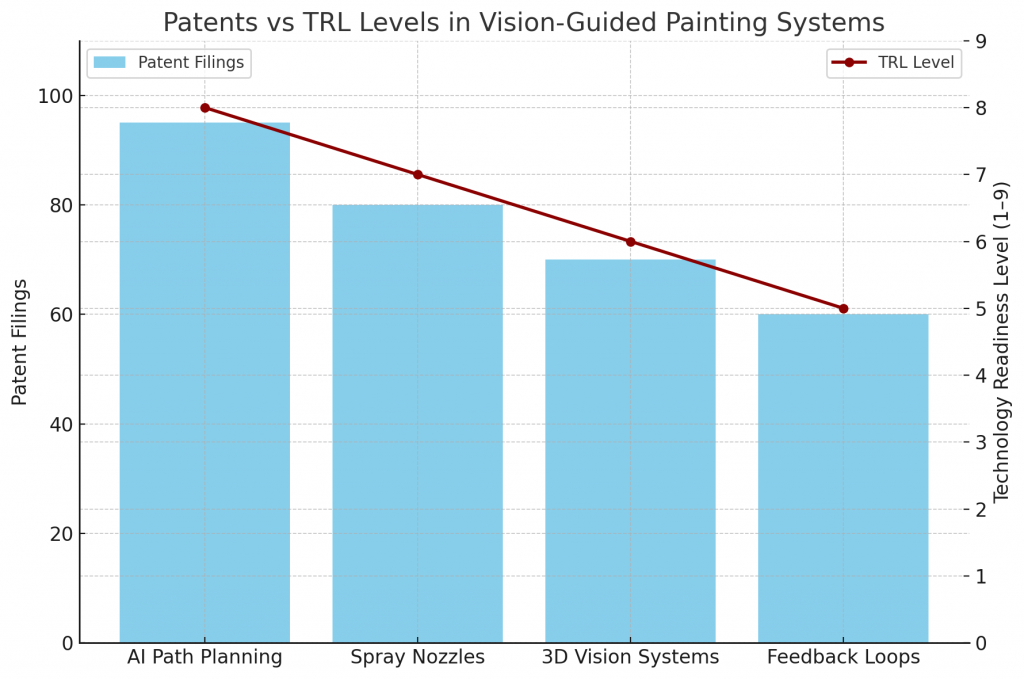

What Do Patents and TRL Levels Indicate?

Patent activity shows innovation in:

- AI-based path planning for painting robots.

- Advanced spray nozzles with adaptive control.

- Multi-camera vision systems for 3D mapping.

- Feedback control loops for coating consistency.

Technology Readiness Levels (TRLs):

- Industrial painting robots: TRL 9, widely deployed.

- AI vision integration: TRL 7–8, moving toward full commercialization.

- Autonomous systems: TRL 6–7, early industrial pilots.

- Smart materials for coatings: TRL 5–6, in R&D.

This reflects both maturity in robotics and growing innovation in AI-driven painting.

What Are the Key Challenges?

Adoption comes with challenges:

- High upfront costs: Investment in robots and vision sensors.

- System complexity: Requires skilled integration and training.

- Maintenance demands: Vision systems need calibration and upkeep.

- SME adoption barriers: Smaller firms face capital constraints.

- Standardization gaps: Lack of uniform frameworks for AI painting.

These challenges highlight the importance of partnerships and strong ROI cases.

What Is the Future Outlook?

The future of vision-guided painting system adoption includes:

- AI enhancements: Smarter real-time decision-making.

- Digital twins: Virtual modeling of painting processes.

- Cloud robotics: Remote monitoring and optimization.

- Green manufacturing: Eco-efficient paints and processes.

- Scalable automation: Expanding adoption among SMEs.

With these advances, vision-guided painting system technologies will be core to Industry 4.0.

How Can PatentsKart Help?

PatentsKart supports innovators in vision-guided painting system technology with:

- Patent landscaping to identify white spaces.

- Freedom-to-operate studies to avoid IP risks.

- TRL benchmarking to assess maturity levels.

- Competitor monitoring to track industry leaders.

- Licensing assistance to accelerate commercialization.

By leveraging insights from PatentsKart, manufacturers can deploy vision-guided painting system solutions confidently.

Conclusion

The manufacturing world is entering a new era of automation and AI. The vision-guided painting system is not just a technological upgrade—it’s a transformation of how coatings are applied across industries. With precision, efficiency, and adaptability, these systems solve age-old challenges in industrial painting.

As companies embrace digital transformation, adopting vision-guided painting system technology ensures resilience, competitiveness, and sustainability. The future of industrial finishing belongs to those who innovate today.

FAQs About Vision-Guided Painting Systems

Q1. What is a vision-guided painting system?

It is a robotic painting system that uses vision and AI to adapt spray paths in real time.

Q2. How does it improve efficiency?

It reduces paint waste, improves coating precision, and cuts rework costs.

Q3. Which industries use these systems?

Automotive, aerospace, consumer goods, heavy machinery, and construction.

Q4. What are the challenges in adoption?

High costs, maintenance needs, and skill requirements are key hurdles.

Q5. How can PatentsKart help innovators?

By offering IP insights, TRL benchmarking, and competitor tracking for smarter decisions.